Inquiry

고객만족을 넘어 고객감동을 추구합니다

Extrusion

Extrusion Process Flow

-

Die Preheating

Die PreheatingDie Preheating

-

Billet Preheating

Billet PreheatingBillet Preheating

-

Extrusion

ExtrusionExtrusion

-

Quenching Heat Treatment

Quenching Heat TreatmentAir Cooling Treatment

-

Straightening

StraighteningStretching

-

Cutting

CuttingCutting Length

-

Artificial Aging Heat Treatment

Artificial Aging Heat TreatmentTemperature & Time Control

-

Final Inspection

Final InspectionDimensional & Visual Inspection

-

Packaging

PackagingPackaging Specifications

-

Delivery

DeliveryShipment

Detailed AL Extrusion Process Flow

| Process | Equipment Name | Photo | Control Item | Detailed Description | ||

|---|---|---|---|---|---|---|

| Symbol | Process Name | Product | Operation | |||

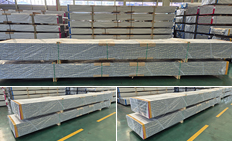

| 1 |

Raw Material Inbound (Billet) AL6063 AL6061 |

Pallet |

|

Verify the chemical composition of the raw material Ensure there is no bending or warping of the material |

Confirm there is no contamination or foreign material present Check for any other deformation or defect |

Receive and inspect raw materials in accordance with the customer’s required quality and specifications |

| 2 |

1.Billet Preheating 2.Die Preheating |

1.Billet Furnace 2.Die Furnace |

|

1.Ensure No Warping

Verify alloy composition (drawing specifications) |

1.Set Billet Heating Temperature

450~500℃ Duration: 20 minutes ± 5 minutes 480℃±20 |

1.Preheating raw material for extrusion forming 2.Preheating the die to prevent interference between material and tooling |

| 3 | Extrusion (Cooling) | Extrusion Press |

|

Verify extruded shape against drawing specifications |

Extrusion Temperature (430℃) Speed (5.8~6.6) |

Perform extrusion and cooling in accordance with design specifications |

| 4 | Straightening / Cutting |

1.Straightener 2.Cutting Machine |

|

1.Check product cooling condition and flatness 2.Verify compliance with customer specifications |

1.Inspect the condition of the straightener press unit 2.Check saw blade and stopper condition |

Cutting operation performed to maintain the shape of the extruded profile and prepare for heat treatment |

| 5 | Heat Treatment | Aging Oven |

|

Hardness Verification |

Temperature / Duration |

Heat treatment process designed to maintain the hardness required by the customer |

-

Extrusion Equipment One 2,000-ton press

-

Extrusion Equipment Two 1,350-ton presses

Inquiry go top